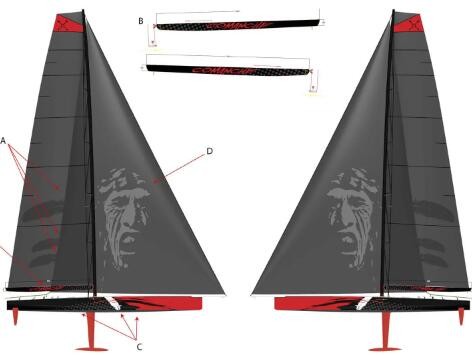

产品简介由 VPLP/Verdier 设计,并在短短 12 个月内在美国最大的海洋烤箱中建造,超级游艇 Comanche 旨在成为有史以来最快的单鸥。 她采用预浸料碳纤维制成,产生了一个非常轻巧和坚固的船体,并具有一个罐头龙骨、水板、镇流器和大帆面积。 Comanche 具有宽、浅的船体和高功率重量比。 Comanche 的成就包括: 打破了近 5 小时的纽波特百慕大赛记录。新的跨大西洋单鸥西东纪录 5 天,14 小时,21 分钟,25 秒(超过 24 小时,比以前的记录快) 先进的建设能力 对于超级游艇科曼奇的建设,店铺的物理空间被彻底改变。 用于烹饪船体和甲板复合部件的模块化烤箱现在完全填充了设施内部,小型烤箱可以处理大楼内部的舱壁和小型零件。 烤箱 目前三个烤箱中最大的是 110 英尺 x 36 英尺 x 20 英尺(33.5m x 11.1m x 6 米)。 屋顶是可拆卸的,墙壁和屋顶是模块化的。 多个加热器的总容量超过 150 万 BTU, 建筑扩建了 大楼,现在有一个 “洁净室”,用于切割织物。 冷藏预浸料材料的储存位于附近。 英文介绍Designed by VPLP/Verdier and constructed in the largest marine oven in the United States in just 12 months, Superyacht Comanche is intended to be the fastest monohull ever built. She is constructed of pre-preg carbon fiber, resulting in an extremely light and strong hull and features a canting keel, daggerboards, water ballast and large sail area. Comanche features a wide, shallow hull and high power-to-weight ratio. Comanche’s accomplishments include the following: Setting the 24-hour monohull speed record of 618.01 miles (traveling at an average speed of 25.75 kts) Line honors at the 2015 Rolex Sydney Hobart Yacht Race Breaking the Newport Bermuda Race record by almost 5 hours Setting the new Transatlantic monohull West East record of 5 days, 14 hours, 21 minutes, 25 seconds (over 24 hours faster than the previous record) Advanced Construction Capabilities For Superyacht Comanche’s build, the shop’s physical space was completely transformed. A modular oven for cooking the hull and deck composite parts now completely fill the interior of the facility with smaller ovens handling bulkheads and small parts elsewhere in the building. The Ovens The largest of the three ovens is currently 110’ x 36.5’ x 20’ (33.5m x 11.1m x 6m). The roof is removable and the walls and roof are modular. Multiple heaters have a combined capacity of over 1.5 million BTU’s. Building Extension The building was extended and now hosts a “clean room” for cutting fabric. Storage of refrigerated prepreg materials is located nearby. |

| 39英尺传统型2舱木质帆船(补助帆桁) |

2023-09-28

|

查看详情 >> |

| 98英尺传统型尾部开放式巡游帆船游艇(一键式航行控制帆船) |

2023-11-14

|

查看详情 >> |

| 37米传统型尾部开放式超级帆船游艇(三桅式补助帆桁游艇帆船) |

2023-11-22

|

查看详情 >> |

| 传统型3舱炭纤补助帆桁巡航竞赛帆船(经典日间游艇帆船) |

2023-12-06

|

查看详情 >> |

| 60米传统型快速巡游超级帆船游艇(铝制甲板会客区竞赛帆船) |

2024-01-05

|

查看详情 >> |