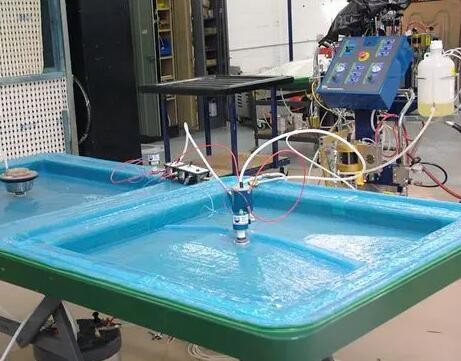

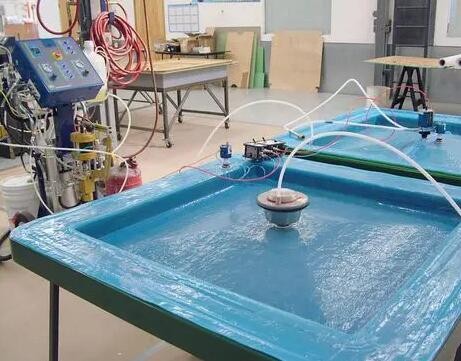

产品简介具有全自动控制功能的气动和PLC泵送系统用于封闭式模具的应用 爱国者创新者RTM系统是为在控制压力下注射聚酯、乙烯基酯和甲基丙烯酸酯树脂和催化剂而设计的。材料的混合是在注射头按要求进行的,催化剂的比例可以从0.75%到2.5%进行调整。该系统有一个独特的控制面板,便于操作。完全气动的自动控制,在注射、再循环等过程中控制冲程数,使过程更容易、更有效率。 特点。 行程数计数器 再循环 树脂凝胶报警器(RGA) 模压保护器(MPG) 自动喷枪的综合控制 涡轮自动喷枪/IVx3/PPVS开/关 冲洗控制 阿特里奥特创新者PLC 规格。 输出能力。高达7.5磅/分钟。(3.4 kg/min.) 取决于材料和应用 催化剂压力:使用PAT CP - 0980时为0.75%至2.5%(体积),使用PAT CP 1530时为1%至3%。 空气消耗量。18 CFM/150 ltrs 泵比:7:1 最大空气输入压力:100 psi (7 bar, 0.7 MPa) 选项。 气动PV传感器 加热器控制 CE防护装置 CFH-4000加热器 涡轮自动喷头 Patriot ™创新者PLC选项 英文介绍Pneumatic and PLC pumping systems with fully automated controls for closed mold applications The Patriot Innovator RTM Systems were designed for injecting polyester, vinylester and methacrylate resins and catalyst at controlled pressures. The material mixing is done on demand at the injection head, and the catalyst ratio can be adjusted from 0.75% to 2.5%. The system features a unique control panel for easy operation. The fully pneumatic automated controls, controlling the number of strokes during injections, recirculation, and more makes the process easier and more efficient. Features: Stroke number counter Recirculation Resin Gel Alarm (RGA) Mold Pressure Guard (MPG) Integrated controls for Auto Gun Turbo Autosprue/IVx3/PPVS on/off Flush Controls ATRIOT INNOVATOR PLC Specifications: Output Capabilities: Up to 7.5 lbs./min. (3.4 kg/min.) depending on materials & application Catalyst Pressure: 0.75% to 2.5% by volume with PAT CP – 0980, 1% – 3% with PAT CP 1530 Air Consumption: 18 CFM/150 ltrs Pump Ratio: 7:1 Maximum Air Input Pressure: 100 psi (7 bar, 0.7 MPa) Options: Pneumatic PV Sensor Heater Control CE Guard CFH-4000 heater Turbo Auto Sprue Patriot ™ Innovator PLC Option |

| 易操作2臂移动船坞除尘器(多功能工业抽气机) |

2023-12-21

|

查看详情 >> |

| 国产切割台(30X 30MM) |

2023-09-25

|

查看详情 >> |

| CNC数控复合纤维织物切割台(船坞自动化切割) |

2023-09-26

|

查看详情 >> |

| 帆布制作缝纫机COASTAL-250(适合缝制针号为130-180的中等重量帆) |

2023-10-31

|

查看详情 >> |

| 船坞剪刀ARAMID(适用于轻薄材料) |

2023-10-12

|

查看详情 >> |